#!/usr/bin/python

#--------------------------------------

# ___ ___ _ ____

# / _ \/ _ \(_) __/__ __ __

# / , _/ ___/ /\ \/ _ \/ // /

# /_/|_/_/ /_/___/ .__/\_, /

#

/_/ /___/

#

#

bme280.py

# Read data from a digital pressure sensor.

#

# Official datasheet available from :

#

https://www.bosch-sensortec.com/bst/products/all_products/bme280

#

# Author : Matt Hawkins

# Date : 25/07/2016

#

# http://www.raspberrypi-spy.co.uk/

#

#--------------------------------------

from periphery import I2C

import time

from ctypes import c_short

from ctypes import c_byte

from ctypes import c_ubyte

import sys

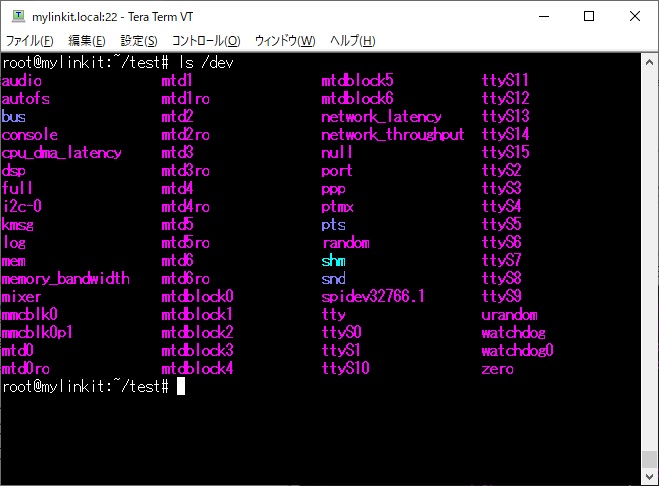

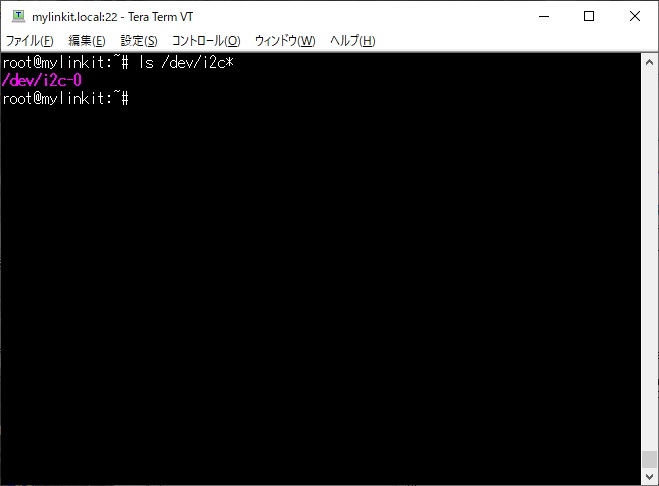

DEVICE = 0x76 # Default device I2C address

argv = sys.argv

argc = len(argv)

if (argc == 1):

device = "/dev/i2c-0"

if (argc == 2):

pin = int(argv[1])

if (pin == 0):

device = "/dev/i2c-0"

if (pin == 1):

device = "/dev/i2c-1"

if (pin == 2):

device = "/dev/i2c-2"

#bus = smbus.SMBus(0) # Rev 2 Pi, Pi 2 & Pi 3 uses bus

1

#i2c = I2C("/dev/i2c-0")

print "device=",

print device

i2c = I2C(device)

def getShort(data, index):

# return two bytes from data as a signed 16-bit

value

return c_short((data[index+1] << 8) +

data[index]).value

def getUShort(data, index):

# return two bytes from data as an unsigned 16-bit

value

return (data[index+1] << 8) + data[index]

def getChar(data,index):

# return one byte from data as a signed char

result = data[index]

if result > 127:

result -= 256

return result

def getUChar(data,index):

# return one byte from data as an unsigned char

result = data[index] & 0xFF

return result

def readBME280ID(addr=DEVICE):

# Chip ID Register Address

REG_ID = 0xD0

# (chip_id, chip_version) =

bus.read_i2c_block_data(addr, REG_ID, 2)

msgs = [I2C.Message([REG_ID]), I2C.Message([0,0],

read=True)]

i2c.transfer(DEVICE, msgs)

chip_id = msgs[1].data[0]

chip_version = msgs[1].data[1]

return (chip_id, chip_version)

def readBME280All(addr=DEVICE):

# Register Addresses

REG_DATA = 0xF7

REG_CONTROL = 0xF4

REG_CONFIG = 0xF5

REG_CONTROL_HUM = 0xF2

REG_HUM_MSB = 0xFD

REG_HUM_LSB = 0xFE

# Oversample setting - page 27

OVERSAMPLE_TEMP = 2

OVERSAMPLE_PRES = 2

MODE = 1

# Oversample setting for humidity register - page

26

OVERSAMPLE_HUM = 2

# bus.write_byte_data(addr, REG_CONTROL_HUM,

OVERSAMPLE_HUM)

msgs = [I2C.Message([REG_CONTROL_HUM,

OVERSAMPLE_HUM]), I2C.Message([0], read=False)]

i2c.transfer(DEVICE, msgs)

control = OVERSAMPLE_TEMP<<5 |

OVERSAMPLE_PRES<<2 | MODE

# bus.write_byte_data(addr, REG_CONTROL, control)

msgs = [I2C.Message([REG_CONTROL, control]),

I2C.Message([0], read=False)]

i2c.transfer(DEVICE, msgs)

# Read blocks of calibration data from EEPROM

# See Page 22 data sheet

# cal1 = bus.read_i2c_block_data(addr, 0x88, 24)

cal1 = [0 for i in range(24)]

msgs = [I2C.Message([0x88]), I2C.Message(cal1,

read=True)]

i2c.transfer(DEVICE, msgs)

cal1 = []

for x in range(24):

cal1.append(msgs[1].data[x])

# cal2 = bus.read_i2c_block_data(addr, 0xA1, 1)

cal2 = []

msgs = [I2C.Message([0xA1]), I2C.Message([0],

read=True)]

i2c.transfer(DEVICE, msgs)

cal2.append(msgs[1].data[0])

# cal3 = bus.read_i2c_block_data(addr, 0xE1, 7)

cal3 = [0 for i in range(7)]

msgs = [I2C.Message([0xE1]), I2C.Message(cal3,

read=True)]

i2c.transfer(DEVICE, msgs)

cal3 = []

for x in range(7):

cal3.append(msgs[1].data[x])

# Convert byte data to word values

dig_T1 = getUShort(cal1, 0)

dig_T2 = getShort(cal1, 2)

dig_T3 = getShort(cal1, 4)

dig_P1 = getUShort(cal1, 6)

dig_P2 = getShort(cal1, 8)

dig_P3 = getShort(cal1, 10)

dig_P4 = getShort(cal1, 12)

dig_P5 = getShort(cal1, 14)

dig_P6 = getShort(cal1, 16)

dig_P7 = getShort(cal1, 18)

dig_P8 = getShort(cal1, 20)

dig_P9 = getShort(cal1, 22)

dig_H1 = getUChar(cal2, 0)

dig_H2 = getShort(cal3, 0)

dig_H3 = getUChar(cal3, 2)

dig_H4 = getChar(cal3, 3)

dig_H4 = (dig_H4 << 24) >> 20

dig_H4 = dig_H4 | (getChar(cal3, 4) & 0x0F)

dig_H5 = getChar(cal3, 5)

dig_H5 = (dig_H5 << 24) >> 20

dig_H5 = dig_H5 | (getUChar(cal3, 4) >> 4

& 0x0F)

dig_H6 = getChar(cal3, 6)

# Wait in ms (Datasheet Appendix B: Measurement

time and current calculation)

wait_time = 1.25 + (2.3 * OVERSAMPLE_TEMP) + ((2.3

* OVERSAMPLE_PRES) + 0.575) + ((2.3 *

OVERSAMPLE_HUM)+0.575)

time.sleep(wait_time/1000) # Wait the

required time

# Read temperature/pressure/humidity

# data = bus.read_i2c_block_data(addr, REG_DATA, 8)

data = [0 for i in range(8)]

msgs = [I2C.Message([REG_DATA]), I2C.Message(data,

read=True)]

i2c.transfer(DEVICE, msgs)

data = []

for x in range(8):

data.append(msgs[1].data[x])

pres_raw = (data[0] << 12) | (data[1]

<< 4) | (data[2] >> 4)

temp_raw = (data[3] << 12) | (data[4]

<< 4) | (data[5] >> 4)

hum_raw = (data[6] << 8) | data[7]

#Refine temperature

var1 =

((((temp_raw>>3)-(dig_T1<<1)))*(dig_T2))

>> 11

var2 = (((((temp_raw>>4) - (dig_T1)) *

((temp_raw>>4) - (dig_T1))) >> 12) * (dig_T3))

>> 14

t_fine = var1+var2

temperature = float(((t_fine * 5) + 128) >>

8);

# Refine pressure and adjust for temperature

var1 = t_fine / 2.0 - 64000.0

var2 = var1 * var1 * dig_P6 / 32768.0

var2 = var2 + var1 * dig_P5 * 2.0

var2 = var2 / 4.0 + dig_P4 * 65536.0

var1 = (dig_P3 * var1 * var1 / 524288.0 + dig_P2 *

var1) / 524288.0

var1 = (1.0 + var1 / 32768.0) * dig_P1

if var1 == 0:

pressure=0

else:

pressure = 1048576.0 - pres_raw

pressure = ((pressure - var2 / 4096.0)

* 6250.0) / var1

var1 = dig_P9 * pressure * pressure /

2147483648.0

var2 = pressure * dig_P8 / 32768.0

pressure = pressure + (var1 + var2 +

dig_P7) / 16.0

# Refine humidity

humidity = t_fine - 76800.0

humidity = (hum_raw - (dig_H4 * 64.0 + dig_H5 /

16384.0 * humidity)) * (dig_H2 / 65536.0 * (1.0 + dig_H6 /

67108864.0 * humidity * (1.0 + dig_H3 / 67108864.0 *

humidity)))

humidity = humidity * (1.0 - dig_H1 * humidity /

524288.0)

if humidity > 100:

humidity = 100

elif humidity < 0:

humidity = 0

return temperature/100.0,pressure/100.0,humidity

def main():

while True:

print("-----------------------")

(chip_id, chip_version) =

readBME280ID()

print "Chip ID

: 0x%x" % chip_id

if (chip_id == 0x60):

print

"Version :", chip_version

temperature,pressure,humidity =

readBME280All()

print "Temperature : {:.2f}

C".format(temperature)

print "Pressure :

{:.2f} hPa".format(pressure)

if (chip_id == 0x60):

print

"Humidity : {:.2f} %".format(humidity)

time.sleep(2)

if __name__=="__main__":

try:

main()

except KeyboardInterrupt:

pass

|